Ultrafiltration Water Treatment System

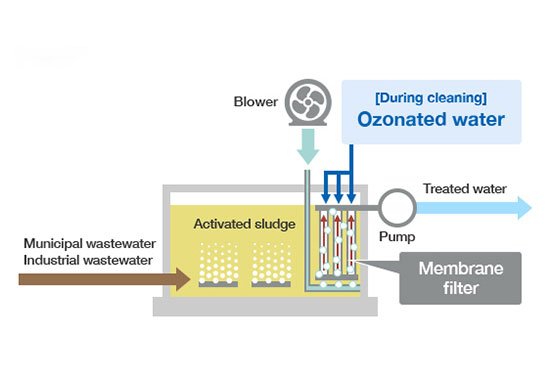

A dependable and economical membrane technology for treating water is ultrafiltration (UF). In order to clarify waste water quality, viruses, bacteria, as well as organic compounds and trace metals, UF systems are used as a pre-treatment for reverse osmosis systems. They are also used to separate suspended solids, organic contaminants, and other particles in drinking and process water. Additionally, UF prevents the fouling and clogging of downstream treatment systems.

Using membrane technology, an ultrafiltration water treatment system filters water to get rid of suspended particles, bacteria, viruses, and other impurities. It works particularly well to purify highly contaminated turbid water that contains both organic and inorganic matter. In order for it to function, pressurised water is forced through a membrane with minuscule pores. Particles that are larger than the pore’s molecular size are caught on the membrane’s surface, while smaller molecules are filtered through and gathered on the other. The membranes can typically be reused without replacement for multiple cycles of filtration, making this a very effective process. Ultrafiltration is a cost- and energy-efficient method of water filtration that can be used to purify water for a variety of purposes.

Most organisms, suspended solids, and macromolecules of physiological and chemical importance are effectively removed by UF membranes because of their pore size, which rejects particles larger than 0.01 microns. Asymmetric UF membranes reject smaller particles through deeper layers while gradually removing larger particles at the surface layers.

The hollow fibre membranes are typically used in UF systems (tubes made of semi-permeable material arranged in a pressure vessel system). Two components are needed for the process: a membrane system to separate contaminants from the water and an external pressure generating system. UF systems can be easily and conveniently automated due to their efficient and effective separation, requiring little upkeep and control adjustments.

With energy costs as low as 1 kWh/1000 gal treated and a smaller environmental impact than other technologies, UF is extremely energy-efficient. UF systems typically have low fouling rates, which lowers average cleaning costs.

In order to extend system life, lower maintenance costs, and effectively remove suspended solids or other particles, pre-treatment of UF systems is necessary.Pre-treatment alternatives include filtration, sedimentation, and coagulation, among others. Additionally, water retention time in the feed tank needs to be kept to a minimum as it increases the possibility of foulant build-up and decreases UF membrane life.

To help remove colloids and suspended particles from UF systems, chemical dosing with polymeric substances or other flocculants is typically necessary. This ensures that the colloids are physically removed before being subjected to chemical adsorption. Reverse osmosis, activated carbon, and ion exchange are a few other cutting-edge technologies that can be added to the treatment process.

Even without prior knowledge of the water’s composition, UF systems can be chosen to meet the highest treatment requirements due to their modularity, scalability, and demonstrated effectiveness. Due to their scalability, UF systems can handle flows of a few litres to several thousand litres per hour. UF systems also have simple maintenance procedures, which are usually limited to backwashing, chemical dosing, and membrane cleaning.

Overall, UF systems are an appealing option for a variety of water treatment applications because they are a dependable and affordable way to treat and remove suspended solids, bacteria, viruses, and other particles from water.

for more blog click here