Tube Cleaning Accessories: An Important Equipment

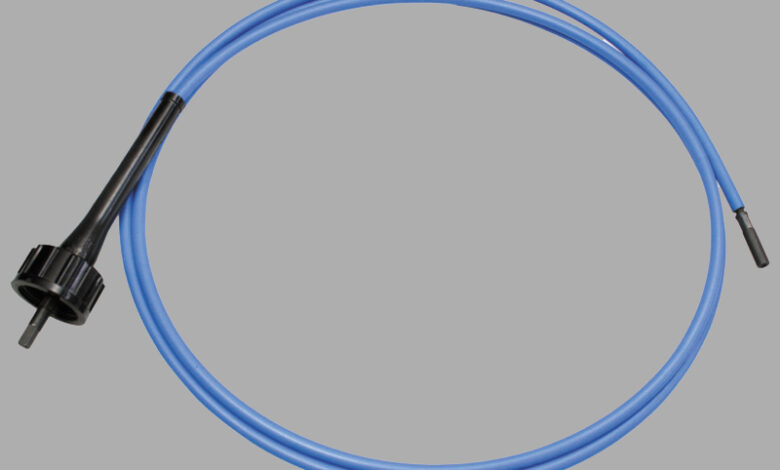

Tube Cleaning System has several advantages. The tube cleaning method is an efficient way to keep shell and tube heat exchangers and condensers free of fouling and scaling. It is renowned as a high-quality, environmentally friendly system that operates on a simple and long-lasting concept. The systems result in significant financial and environmental savings. The Tube Cleaning Accessories have proven to be extremely important for all households. The Tube Cleaning Accessories manufacturers utilise this scenario to make tremendous profits. This article talks in detail about the various benefits related to those accessories.

Significant Benefits of Tube Cleaning accessories:

- Lowers the overall cost: Fouling expenses include costs associated with energy inefficiency, lost manufacturing capacity, and cleaning disruptions. When Eqobrush is used, total fouling costs are reduced because fouling is prevented from affecting the tubes in the equipment.

- Operational downtime is minimised: The automated and online cleaning method eliminates planned tube cleaning downtime. Because tube corrosion is prevented, unplanned downtime for repairs or plugging leaky tubes will be a thing of the past.

- There is no need for mechanical or chemical cleaning: Cleanings that are unpleasant and harmful to the environment are no longer required, which saves time and money in terms of manpower, chemicals, and taxes.

- Reduce your use of electric energy: Improved heat transmission results in a lower approach, which can save up to 30% on energy costs. This corresponds to double-digit savings on the total power expenditure in building operations! The power savings enable for a normal payback period of less than a year on your investment, and the compounded savings over the life of the chiller far outweigh the chiller’s replacement value.

- Mitigates use of fossil fuel sources: In power plants, a lower condensate temperature results in a higher steam vacuum, which boosts capacity and fossil fuel efficiency.

- Reduces energy use in the various system pumps: A 10% reduction in flow surface (produced by a 1mm scaling layer in a 25 mm tube) causes pressure loss, which takes 30% more pump energy to overcome (cubic law). In the alternative, a reduced flow rate increases heat transfer speed and overall system performance.

- The capex for latest products should be reduced: Because fouling would no longer occur, the fouling factor that is frequently included in system design (between 25 and 100 percent of increased heat exchange surface) may be ignored. CAPEX is reduced when units are smaller.

- Extend the equipment’s life duration: There will be no more premature equipment replacements due to heat transfer efficiency losses produced by leaky tubes (due to corrosion) that have been plugged. Because the compressor is operating at a lower overall capacity, its lifespan is extended.

- Save both money and harmful effect of chemicals: Cleanings that are unpleasant and harmful to the environment are no longer necessary, resulting in time and money savings in labour and chemical costs, as well as fees for cleaning chemical discharge.

These were some of the phenomenal benefits of the tube cleaning accessories. The Tube Cleaning Accessories Suppliers earn huge profits from the various accessories. The Portable Pneumatic Tube Cleaners Suppliers are also in fashion nowadays.